The aim – an international legally binding instrument (ILBI) on plastic pollution – is the world’s chance to sufficiently incentivize circularity and enhance waste management infrastructure.

Let’s work together to end plastic pollution

We support a global plastics pollution agreement that helps scale action, accelerates plastics circularity, and unlocks the value of plastic waste.

Our position on the Global Plastics Pollution Agreement

“Speaking for Dow and the broader industry, we’re heavily engaged in trying to make sure that we do reach a global treaty that can be legally binding and to do that, we want as many countries as possible to be party to that. That means a change in the way we do things. That’s transformational.”

Jim Fitterling, Chair and CEO, Dow

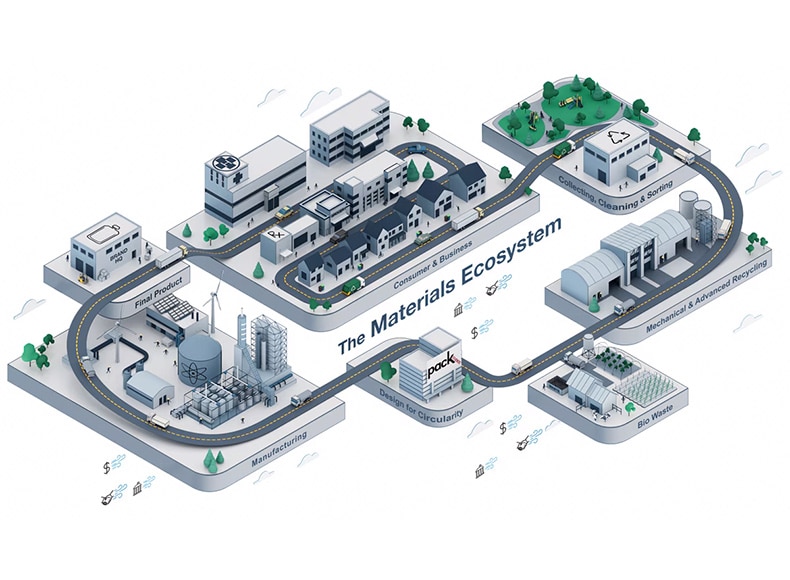

The global plastics value chain is highly interlinked and interdependent. It will take every stakeholder – from resin producers to converters, brand owners, governments, communities, and waste management – working together to make change happen to end plastic waste.

We envision a world where products are designed, manufactured, used, re-used and responsibly disposed of in a way that maximizes their value again, and again. We support an agreement that promotes:

- Circularity-enabling policies and blended public-private financing models to ensure adequate funding for effective, self-sustaining waste management tools and systems.

- Producing, designing, and consuming plastics sustainably and equipping parties with tools to establish well-functioning waste management.

- A technology-inclusive approach to address hard-to-recycle plastics and scale circular solutions.

The United Nations (UN) estimates approximately 3.6 billion people – nearly half the global population – lack access to basic waste management. Yet, according to the Organization for Economic Co-operation and Development (OECD), building self-sustaining waste systems globally will cost over $1 trillion.

A global plastics pollution agreement must address how to finance developing the waste management capacity needed to end plastic pollution in a socially inclusive way.

Extended Producer Responsibility (EPR) or similar schemes, where the plastics value chain takes financial and operational responsibility for everything from raw materials to end-of-life and recycling, are a key funding tool for achieving this goal.

To build effective circular infrastructure, ERP schemes must also be material-inclusive and recognize the role of the informal waste sector in many countries – International Labor Organization (ILO) figures estimate 15 million people pick and sort the world’s metropolitan waste globally.

Learn more about EPR and other public-private financing models that can help build better waste management systems in our framework for a sustainable future.

With increasing demand for plastics in many critical applications and sectors, it is important that consumption and production of plastics are sustainable.

Targeted approaches to consumption take into consideration the unique circumstances of each country, as well as the lifecycle, commercial availability, and affordability of plastics alternatives, and avoid a detrimental one-size-fits-all approach and regrettable substitution.

We call for a global plastic pollution agreement that equips countries with tools to build self-sustaining and well-functioning waste management and mitigates socio-economic impacts. Specifically, the ILBI on plastic pollution should drive countries to establish circularity enablers, like:

- Mandates for higher recycling rates.

- Recycled content plastic targets in new products.

- Mandates for recyclability of materials.

- Material- and socially-inclusive well-designed EPR or alike schemes.

The ILBI on plastic pollution should also include universal product design principles based on life-cycle assessments. These can lead to increased recycling and reuse and promote circularity in product designs.

The ILBI on plastic pollution must enable the broadest range of plastic waste to be recycled and thus, support a range of environmentally-sound recycling technologies and continual advancements in innovation.

By enabling a suite of recycling technologies, we can achieve a major leap in the portion of plastics that can be recycled -- especially hard-to-recycle plastics.

Learn more about the advancements in recycling and how they accelerate circularity in our framework for a sustainable future.

Plastic waste has value. Today, science and economics have a way to take plastic waste, break it down into its basic building blocks and turn those building blocks into something useful again.

There is immense growth potential in a recycling industry that includes evolved waste management systems. We estimate current rates of recycling growth could drive $60 to $90B in investments –with about $100B more for collection and sortation—all while creating about one million new jobs.1

What’s more, with these economic opportunities come more ways to reduce carbon emissions because plastics circularity and climate action go together. Expanding the use of circular feedstocks from plastic waste will contribute to the industry’s net zero goals by lowering carbon emissions in manufacturing products and packaging by reducing the amount of fossil fuels used in making them.

Dow is also evaluating and revaluating manufacturing processes to produce packaging with as little carbon emissions as possible. We have a roadmap outlined which enables Dow to decarbonize our manufacturing while growing.

This roadmap includes replacing end-of-life assets with high-efficiency, low-emissions assets. This includes a multi-generation site decarbonization plan for each of our top 12 sites globally – which account for ~90% of our emissions. For example, Dow intends to build the world’s first ever zero carbon emissions (scope 1 and 2) cracker complex in Ft. Saskatchewan, Alberta and is working with X-energy to bring advanced small modular technology to our Seadrift, Texas site to replace energy and steam assets with safe, reliable, low-GHG-emissions power and steam.

As this new industry grows, Dow recognizes the need for a systems approach and is actively adopting new ways of working by investing in technologies, value chain partnerships, business models and waste management infrastructure. A global plastics pollution agreement can help accelerate the creation of a materials ecosystem and bring this system to scale.

1Estimates based on investment and job creation data from the U.S. Environmental Protection Agency, the American Chemistry Council, and The Recycling Partnership.

Global Plastics Treaty at Davos

Watch “Landing an Ambitious Global Plastics Treaty” session from the 2024 WEF Annual Meeting in Davos.

Creating Solutions to Eliminate Plastic Waste

In our Seek Together™ blog, Dow CEO, Jim Fitterling, discusses our support for the creation of an effective international legally binding instrument on plastic pollution.

Global Plastics Treaty: the journey of the past five meetings

On Plastics Unwrapped, we look back on the 5 meetings of the INC and discuss how we can find middle ground between industry and policy to end plastic pollution for good.

Materials

Ecosystem

A materials ecosystem is developing around plastic and renewable waste to deliver its total value.

Design for Circularity,

Together

Pack Studios™ is the connected platform to collaborate on innovative design and accelerate circular packaging.

Building a global plastics pollution agreement that works for all: Is there a path to progress?

In this Business Green article, Jihane Ball, lead sustainability director at Dow, discusses the importance of a global plastics pollution agreement and the role of meaningful stakeholder collaboration