By definition, waste is unwanted, requires disposal and is not always valued. However, when science and economics find a way to take this unwanted material, break it down into its basic building blocks and turn those building blocks into something useful again, plastic waste is transformed and takes on value.

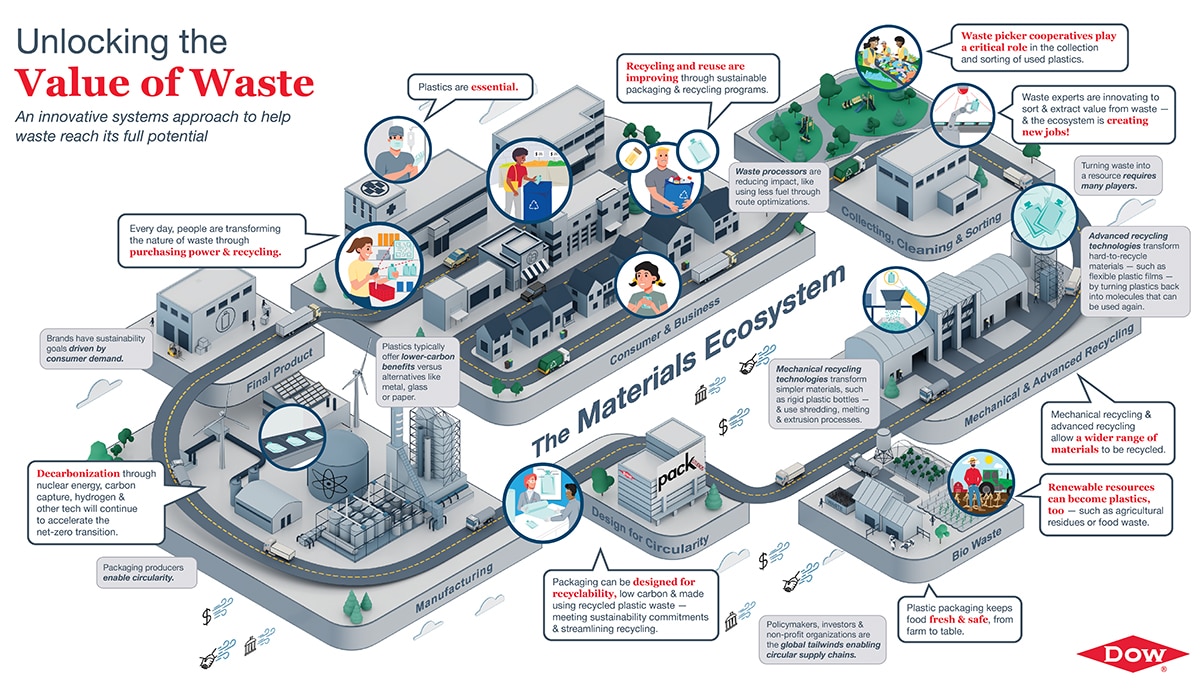

A materials ecosystem is developing around plastic and renewable waste to deliver its total value. The materials ecosystem adds value to plastic waste through recycling technologies and circular solutions.

By repeatedly converting plastic waste into new products, less waste ends up in landfills, incinerators or as environmental leaks.