Dec 5, 2025 | Case Study | 6 minute read

Dec 5, 2025 | Case Study | 6 minute read

Dow is applying a systems approach across the vehicle lifecycle, from material design and component engineering to recycling infrastructure and end-of-life vehicle recovery.

As the automotive industry advances toward a more sustainable future, rapid innovation plays a vital role in improving vehicle efficiency. Lear, a global leader in automotive seating, Jaguar Land Rover (JLR), the British car manufacturer, and Dow have partnered to co-develop a new automotive seat cushion made from lighter, more sustainable materials designed for recyclability at end-of-life. JLR, committed to sustainable design, plans to feature these innovative cushions in its luxury vehicles demonstrating how industry collaboration drives meaningful progress.

Original equipment manufacturers (OEMs) and automakers are under growing pressure to reduce emissions and enable recyclability for vehicle components, such as automotive seat cushions.

While publicly stated targets, such as reducing vehicle lifecycle impacts, are important, policy plays a role in setting the pace and scale of the innovations that help a company meet its goals and address existing and anticipated sustainability-related regulations.

Public policy can create enabling conditions for innovation and act as demand pull measures for sustainable solutions. For example, the proposed End-of-Life Vehicles regulation aims to set mandatory recycled content targets for the plastic parts of cars. It also looks to improve recyclability and overall circularity of end-of-life vehicles. As the policy process enters its final stage, the industry is preparing for the new requirements, considering an opportunity to incorporate more sustainable solutions.

Jennifer Kempf, MobilityScience™ President at Dow, sees firsthand how OEMs and brands are turning policy compliance into a strategic advantage: “Whether our customers are considering regulations in place now or coming soon, compliance is a driver for sustainability innovation that reduces risk and builds lasting value. To support this, Dow is applying a systems approach across the vehicle lifecycle, from material design and component engineering to recycling infrastructure and end-of-life vehicle recovery.”

This is a unique moment in the automotive industry’s history.

“OEMs are shifting from linear to circular throughout the entire vehicle lifecycle – from design to dismantling. This transformation is further accelerated by the influence of public policy, including zero-emission mandates, carbon disclosure requirements, or the End-of-Life Vehicle regulation. To remain compliant, meet the needs of our clients, and uphold our commitment to being a responsible business, we’re innovating across our entire value chain.”

– Alison Nuttall, Head of Sustainability Global Affairs, JLR

Lightweighting in the automotive sector refers to building vehicles that weigh less than previous generations. Vehicle lightweighting not only enables better fuel efficiency, it also can improve braking, handling, acceleration and can increase the battery range on electric vehicles (EVs) and hybrids. Plastics make up 50% of the volume of a modern vehicle but only about 10% of its weight1. This lightweight advantage is why automakers are increasingly turning to plastic innovations, not only to meet exacting performance standards but also to raise the bar on sustainability and recyclability.

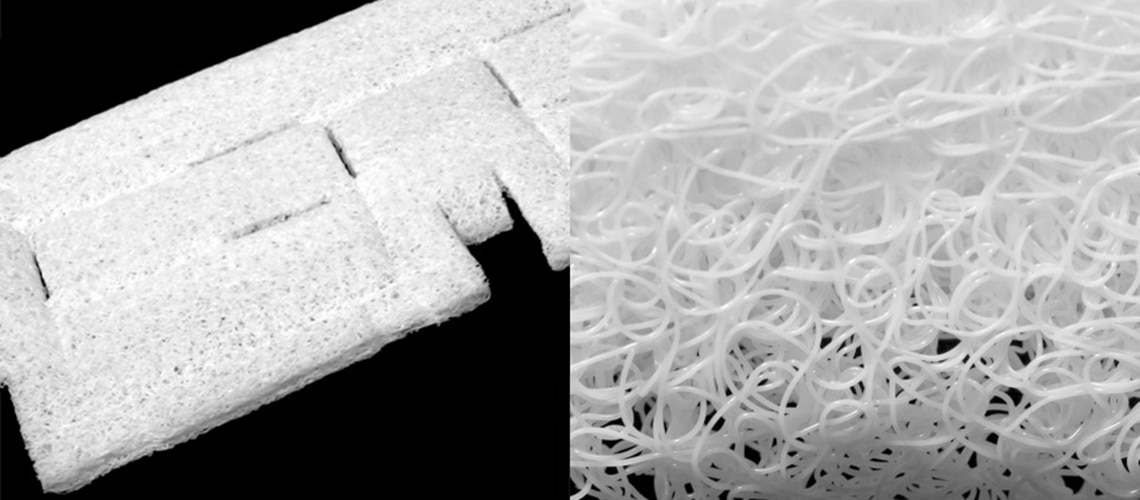

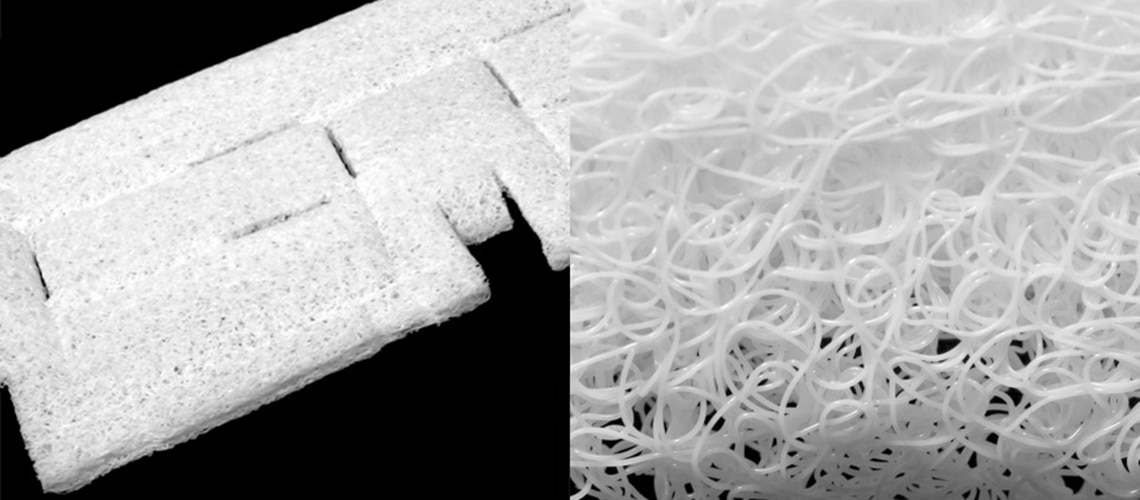

Dow’s innovative 3D Loop technology, INFINAIR™ Polyolefin Elastomers

To help address this need, Dow’s MobilityScience™ team collaborated with Lear to leverage INFINAIR™ Polymers for Loop Technology which is utilized within Lear’s FlexAir™ technology products, offering a more sustainable alternative for automotive seat cushions.

The INFINAIR™ Polymers for Loop Technology for Lear’s FlexAir™ technology fuses thermoplastic elastomer filaments which supports the forming of thousands of bonded loops through a melt-extrusion and water-cooling process developed by Lear. The 3D Loop material made with INFINAIR™ Polymers for Loop Technology offer airflow, support and comfort. This complex blend of elastomers can be adjusted to meet a wide variety of uses—from mattresses to outdoor furniture.

Based on these breakthroughs, Dow’s Pack Studios™ further tuned the product, determining the optimal resin compound and producing pilot batches for testing.

Dow then partnered with Lear, who pioneered proprietary manufacturing processes to extrude, cut, and form the 3D Loop material into automotive seat cushions, while also developing new trim-attachment methods that preserve a single-material system to support recyclability.

Lear advanced the technology into cushions with complex, eye-catching geometries and engineered zoned comfort support. According to Lear, the FlexAir™ technology supports recycling of the entire cushion and has the potential to reduce carbon dioxide equivalent (CO2e) emissions by up to half while reducing seat assembly weight by as much as 20%.

“Through collaboration, we're developing innovations that meet the expectations of our clients and regulatory bodies, without compromising on quality.”

–Dave Withey, Technical Specialist - Seating Innovation & Comfort, JLR

How does this innovation contribute to vehicle sustainability?

As automakers face increasing pressure to meet policy-related requirements and ambitious sustainability targets, they are turning to suppliers like Dow for solutions that support circularity and reduce environmental impacts. This is where materials science innovation plays a critical role—enabling the development of components that meet voluntary commitments and regulatory requirements, while also giving manufacturers a competitive edge.

This case study was developed by a cross-discipline team representing materials, mobility and market expertise across Dow, in collaboration with our customer, Lear. To learn more about the breadth of innovative products and technologies made possible through science and collaboration, visit dow.com.

FlexAir™ is a trademark of Lear Corporation.