Can technology make Dow a safer place to work?

We’re constantly seeking out new ways to make our industrial workplaces the safest of their kind in the world. Our investment in drones and robotics technologies reflects this commitment to the safety of each and every one of our employees.

Nothing should happen at work to prevent an employee from returning home safely every evening.

That sounds easy enough. But as an employer of tens of thousands of people worldwide – many of them working in manufacturing facilities in the chemical industry – that’s our most serious and sancrosant duty.

Whether in Midland, Mumbai, or Melbourne, the safety of our people and the communities in which we operate is at the heart of everything we do.

BUSINESS CHALLENGE

Eliminate workplace fatalities and reduce serious injuries

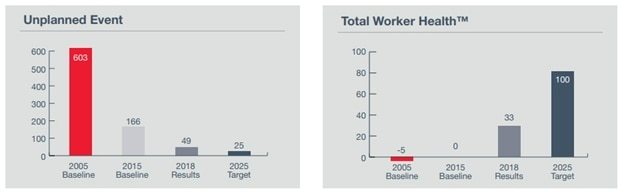

We’re working to eliminate all fatalities by 2025 and reduce the most severe injury and illness incidents by 85 percent compared to 2015.

Measurable improvements in workplace safety are only possible through continuous investment in tools, technologies, and processes. That’s why we’ve empowered our Safe Conditions team to allocate dedicated corporate funds for high-priority safety projects – there were 157 such projects in 2018 alone.

Two of the paramount targets of our 2025 Operations Performance Goal are eliminating fatalities and serious injuries at Dow facilities worldwide.

Serious injuries include fatalities, high-consequence injuries (injuries with long-term impact) and injuries that had the potential to have life-altering impact if circumstances were only slightly different. Our 2025 target is to “eliminate fatalities, reduce severe injury and illness incidents, and maintain total recordable injury and illness rate at industry leading levels.”

To help achieve this, we’re using innovation to protect workers from the most hazardous jobs at Dow.

APPROACH TO SOLVE

Make technology do the dangerous work

We don’t hesitate to take action to preserve the health and wellbeing of our team.

For example, in 2017 we made the unpopular decision to ban employees and contractors from accepting incoming or outgoing phone calls while driving, even when a hands-free system such as Bluetooth® can be used. In 2018, we were proud to report 0 severe Motor Vehicle Accidents.

While we prioritize workplace safety everywhere, there’s no doubt that some jobs are inherently more dangerous than others.

To reduce the likelihood of severe injuries resulting from known high-risk scenarios, we’re leading the industry in introducing state-of-the-art technologies to remove workers from hazardous activities.

For example:

- Dow is using drones for inspections under water, in elevated locations and and in confined spaces instead of putting people at risk. Inspections identify immediate maintenance issues and help anticipate site-specific issues so preemptive action can be taken.

- In 2017, Dow eliminated more than 200 confined space entries using robotics for tank inspections. Inspections with robotics and drones help to eliminate safety risks, optimize productivity and improve cost.

- We are also implementing robotic high-pressure water cleaning and protection devices on aerial lifts.

SOLUTION

750,000 Fewer Hours of Worker Exposure to Higher-Hazard Activities

We continue to demonstrate a safety record well ahead of our peers in the manufacturing sector and chemical industry, and we’re increasingly achieving this by using technologies like robotics and unmanned aerial vehicles to improve worker safety.

Specifically, we’ve already reduced exposure to higher-risk situations by more than 750,000 hours using a wide range of new technologies for confined space entry, elevated work and industrial cleaning.

And by using robotics in 2018, Dow eliminated more than 1,000 confined space entries and more than 1,000 external inspections that would have required elevated work.

Wherever it’s possible to avoid putting people at risk, we’re seeking out ways to deploy robots and drones instead. And to support the adoption of new technologies, our total annual spend on safety in 2018 was the highest since the high-priority program was established in 2014.

All of this ties back to our Safety Culture and our World-Leading Operations Performance Goal, which targets to “eliminate fatalities, reduce severe injury and illness incidents and maintain its total recordable injury and illness rate at industry-leading levels.”

Read more about Dow’s Environmental, Health and Safety (EH&S) practices in the Dow 2017 Sustainability Report and the Dow 2018 Sustainability Report.