The Edison Awards is a prestigious program that honors excellence in product and service innovation. For decades, Dow innovations have been recognized by the Edison Awards for their breakthrough developments, human-centered design and more.

Edison Awards

Dow in the 2025 Edison Awards

For the eighth consecutive year, Dow has received more Edison Awards than any other company. Ten Dow innovations have been recognized with one gold, four silver, and five bronze Edison Awards in 2025. This milestone marks Dow's twelfth consecutive year of winning Edison Awards, a feat unmatched by any other company.

TRITON™ FCX Surfactants

Received a gold award in the Toxin-Free & Health-First Materials category. This biodegradable alternative to fluoro-containing materials offers improved performance and sustainability benefits for paint formulations. Dow’s patented, multifunctional TRITON™ FCX Surfactants prevent freshly painted surfaces from sticking together and demonstrate ease of use, making them safer for end users and cost-effective for paint formulators, compared to fluoro-containing materials.

DOWFROST™ LC Heat Transfer Fluid

Received a silver award in the Datacenter & Power Systems Optimization category. This technology is used for direct-to-chip cooling in data centers, offering better heat removal and corrosion protection than air cooling. It reduces energy consumption, extends IT equipment life, is minimally toxic, and has been tested for long-term reliability.

DOWSIL™ IE-9100 Emulsion

Received a silver award in the Advanced Coating & Surface Protection Materials category. It matches the performance of fluoro-containing products, offering durable water repellency for fabrics with 81% bio-based material. Easy to dilute and combine, the performance has been tailored for synthetic, natural, and blended fiber fabrics. It supports stain protection, retains color vibrancy, and maintains fabric breathability.

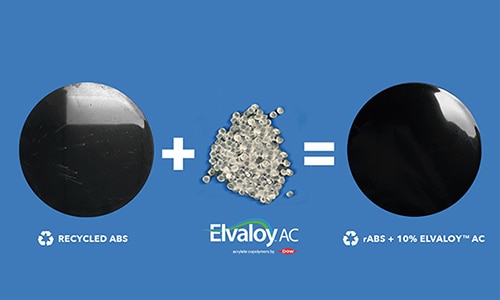

ELVALOY™ AC Acrylate Copolymers

Received a silver award in the Circular Design category. It improves impact performance, processability, and surface appearance of recycled polyacrylonitrile butadiene styrene (ABS) boosting its properties to match virgin ABS while using existing equipment for easy implementation. Additionally, it can enhance the end-of-life recyclability of automotive, electronic, and household appliance parts made from either recycled or virgin ABS.

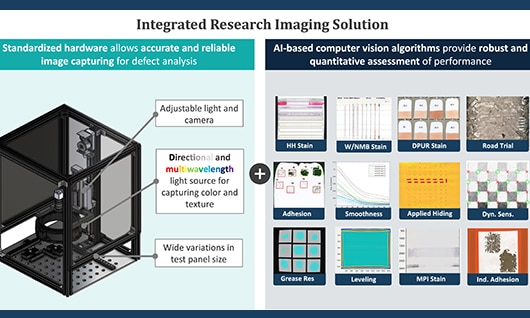

Integrated Research Imaging Solution

Received a silver award in the AI for Creative & Analytical Productivity category. This advanced imaging system leverages AI to enhance paint and coatings assessment. By translating subjective "look and feel" evaluations into robust, quantitative metrics, it ensures reliable performance testing and efficient product development, paving the way for a data-driven future in laboratories.

DOWSIL™ 650+ Protective Peelable Coating

Received a bronze award in the Advanced Coating & Surface Protection Materials category. This technology is a waterborne peelable acrylic coating for temporary protection of façade glazing, window systems, and panels. Applicable to various materials, it offers optimal protection, easy application, and optimal peel-off. Formulated without alkylphenol ethoxylates (APEO)* and with low VOC content, it exemplifies environmental responsibility and sustainability.

*DOWSIL™ 650+ Protective Peelable Coating is APEO free, being manufactured without the use of APEO surfactants.

DURATRACK™ WH-155 Hybrid Emulsion

Received a bronze award in the Smart Urban Mobility Infrastructure category. Designed for two-component waterborne traffic marking paints, it improves drying time and durability in various conditions when applied in thicker applications vs. conventional water-based traffic paints. It offers similar handling and durability as cold plastics, but with low odor, less hazardous labeling, and is a water-based solution. Its distinct composition helps enable high retro-reflectivity and whiteness with minimal TiO2.

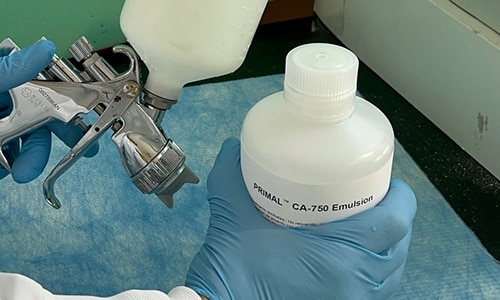

PRIMAL™ CA 750 Adhesive

Received a bronze award in the Toxin-Free & Health-First Materials category. It is a new generation water-based, single-part alternative to allergenic poly(chloroprene) for bonding foam, textiles, and wood in mattress and furniture construction. This user-friendly compound can be applied by spray or roll coating and uses a unique blend of natural materials and polymer chemistry to create instant tack and strong, flexible bonds.

REVOLOOP™ Recycled Plastic Resins for Stretch Applications

Received a bronze award in the Sustainable Product Packaging category. This technology incorporates post-consumer recycled (PCR) plastics and offers a 40% lower carbon footprint than stretch films made with all virgin plastic. Stretch films containing 30% REVOLOOP™ Recycled Plastics Resins are cost-effective, suitable for hand and machine wrapping, and offer up to 2x elongation. Commercially used in Colombia, Guatemala, and the Dominican Republic, 400,000 pallets have been wrapped, leading to significant carbon dioxide equivalent (CO2e) savings.

SPECFLEX™ Technologies for Low Emission and Odor Sustainable Mobility

Received a bronze award in the AI for Environmental Sustainability category. As the leading artificial intelligence (AI) model for low VOC/odor polyurethanes, digitalized SPECFLEX™ Technologies support sustainable mobility by offering customers a broad space to design new, high-quality, ultra low VOC/odor polyurethane foams with exceptional speed and accuracy.