Dec 13, 2024 | Case Study | 5 minute read

Dec 13, 2024 | Case Study | 5 minute read

Collaboration powers the future of innovation.

Dow and Carbice have a groundbreaking partnership to offer advanced thermal interface materials for various industries, including mobility, industrial, consumer electronics, and semiconductors. Unveiled at The Battery Show North America in 2024, this partnership combines decades of Dow’s silicone expertise with aligned carbon nanotube (CNT) technology from Carbice. The collaboration supports innovation for diverse applications through thermal management solutions that are reliable, affordable, and customizable.

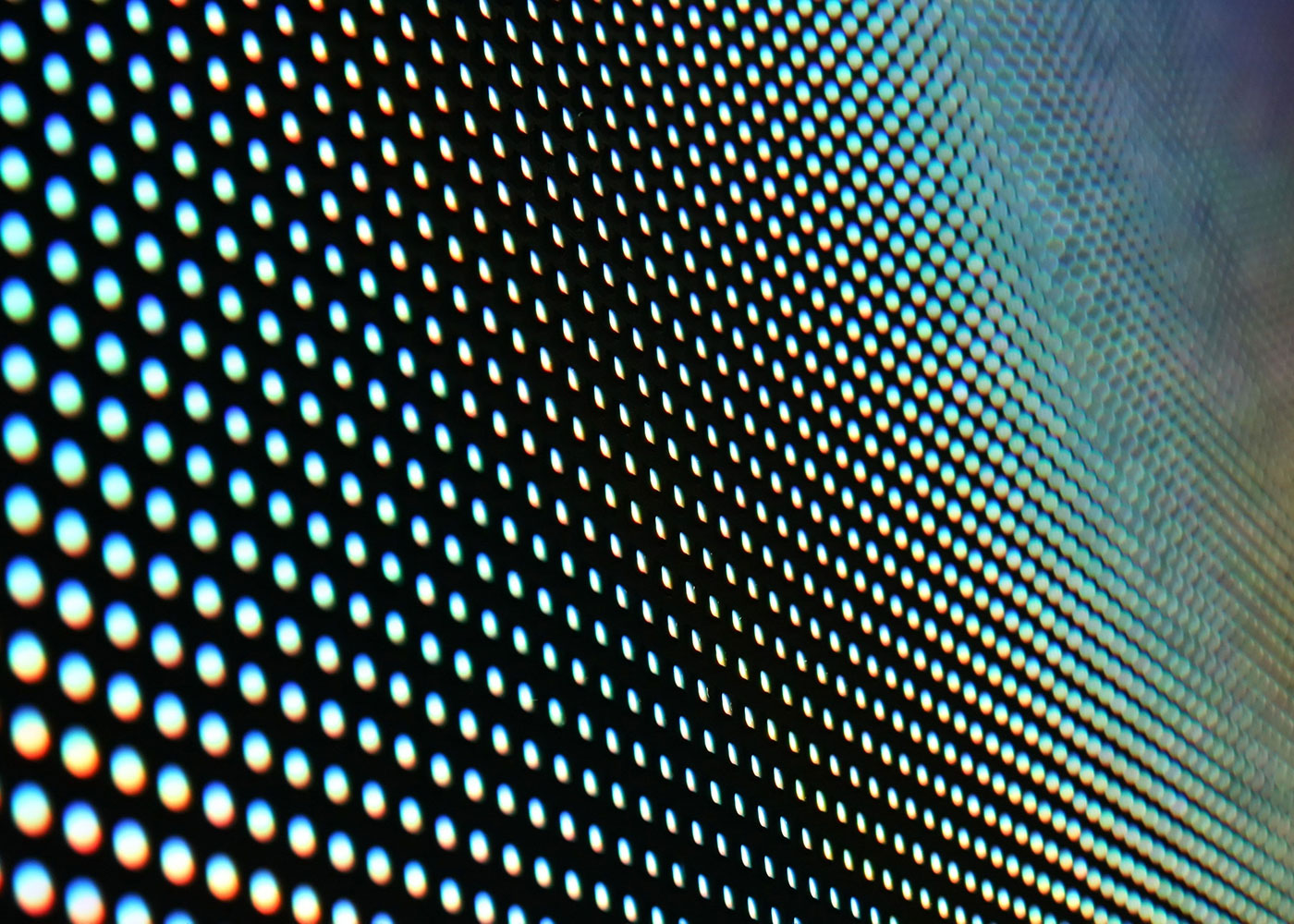

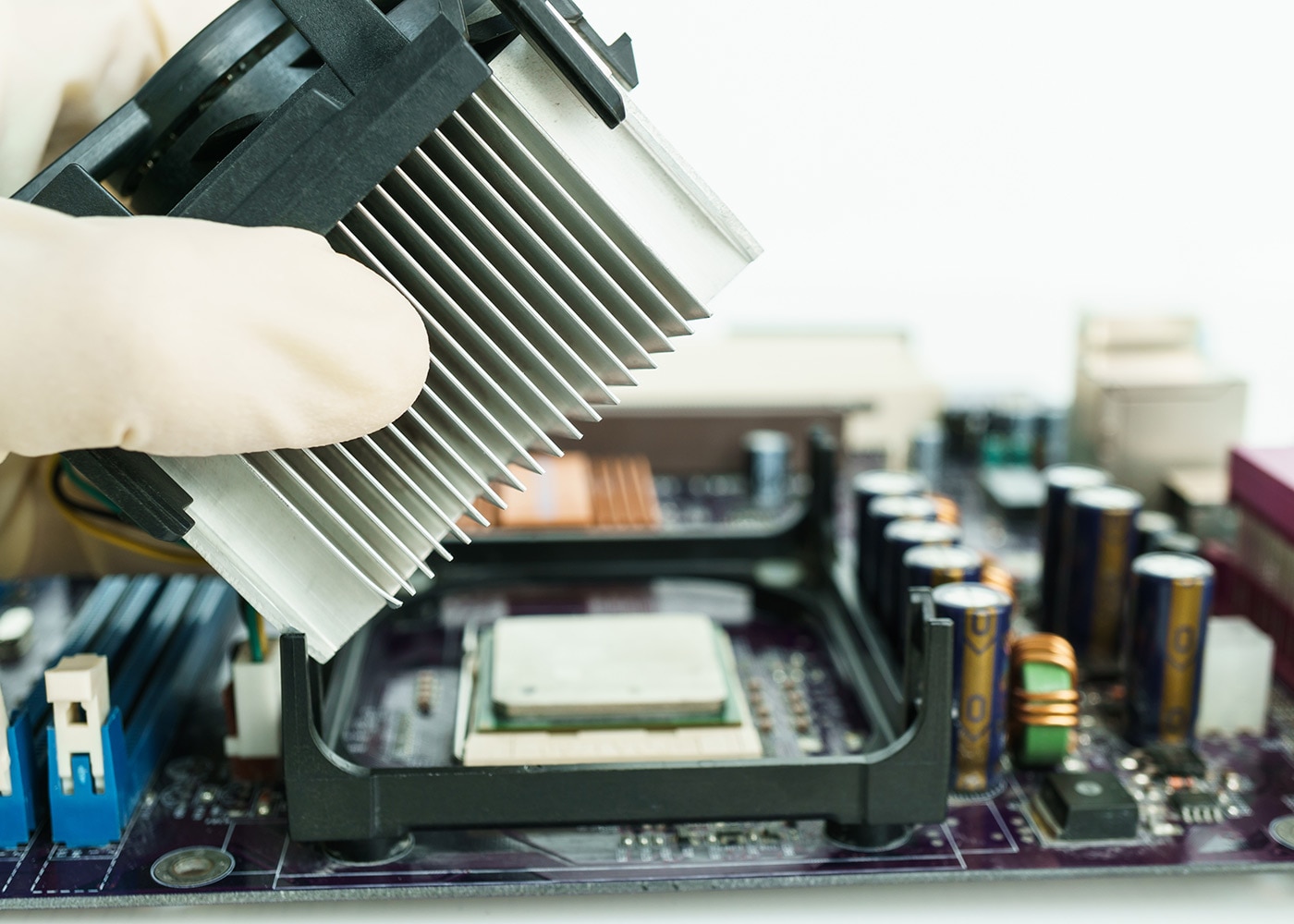

A thermal interface material (TIM) is a material placed between two parts—like a heat-generating device and a heat sink—to help with heat transfer. In electronic devices, gaps can form because of rough surfaces, manufacturing flaws, or misalignment during assembly. These gaps have lower thermal conductivity than solid materials, leading to higher thermal resistance and poor heat dissipation. This can cause hotspots, overheating, or even device failure.

Have you ever noticed your PC or cell phone getting hot when you use it for a while? This happens because of electrical resistance, where the flow of electricity creates friction and generates heat. This heat can slow down your device and affect its performance. That is where thermal interface materials (TIMs) come in. They help transfer heat away from the hot parts, keeping your device cool and running smoothly.

Dow builds on silicone’s inherent potential by combining it with industry-leading materials knowledge, application expertise, customer collaboration, and a global footprint. This continues to be true in our partnership with Carbice.

The following sections elaborate on our industry-leading product portfolio of heat transfer solutions and highlight the new materials from the partnership.

DOWSIL™ thermally conductive silicone adhesives are suitable for bonding and sealing hybrid circuit layers, semiconductor components, heat spreaders, and other applications that demand broad design, flexible processing options and excellent thermal management.

The high-performance materials in our portfolio encompass moisture-cure grades for simple, room-temperature processing as well as heat-cure solutions for speeding productivity and time to market.

Carbice® SA-90 with Silicone Adhesive provides exceptional thermal performance with the functionality of an adhesive. It offers unique assembly benefits by reducing the need for mechanical fastening and can be easily adopted in pick and place processes. The thermal pad ensures reliable high thermal temperature stability, thanks to Dow Silicone technology, and remains re-workable for component adjustments.

DOWSIL™ thermally conductive silicone compounds deliver high conductivity and low resistance to efficiently draw heat away from sensitive printed circuit board (PCB) components and dissipate it into the ambient environment. Silicone-based compounds allow for reworkability and ease of application.

Carbice® SW-90 with Silicone Wax offers performance like a liquid with the user experience of a pad. The robust base pad by Carbice eliminates concerns of pump-out behavior, while Dow Silicones provide enhanced temperature range and stability. It ensures better contact for heat transfer on non-regular surfaces, thanks to its exceptional wettability. The wax is tuned to the temperature requirements for TIM, and its tacky but non-adhesive nature allows for easy removal on demand.

DOWSIL™ thermally conductive silicone gap fillers are soft, compressible solutions specifically formulated to process easily from the original packaging with minimal to no additional process preparation.

They avoid slumping on vertical surfaces during assembly and maintain their vertical stability after cure, even after long use. These highly advanced silicone formulations dissipate heat away from PCB components by efficiently conducting it to a heat sink.

By creating a TIM through the integration of silicone with CNTs, we can develop robust thermal management solutions with excellent interface contact, thereby reducing stress transfer for reliable performance across applications and environments.

Carbice CNTs are durable, reworkable thermal pads and can be effective on uneven surfaces when combined with Dow liquid silicones. Dow liquid silicones can be dispensed exactly where needed and can be enhanced in strength when combined with Carbice pads. Together, these materials complement each other and enable superior performance, customization, and thinner bond lines.

The versatility of silicone chemistry can help expand design freedom, increase processing options, and ultimately enhance the performance and reliability of the devices and machines we use every day.

From race to road, vehicles are increasingly reliant on PCB system assemblies for everything from power electronics systems to propulsion and braking. As this trend accelerates, it will drive demand for higher performance and more cost-effective thermal management solutions.

Unlike conventional light sources, the ability to manage the temperature of an LED module has a direct impact on the reliability, output quality, lifetime and system cost of the device. Moreover, thermal management is becoming an increasingly important performance metric for the entire LED value chain, as solid-state lighting competes with conventional illumination for high-intensity and high temperature applications.

Form factor optimization is one of the challenges facing this industry. Slim, high-powered consumer devices require compact, multifunctional thermal management solutions.

The trend toward smaller devices with more densely packed PCB system components is converging with expanded use of flip chip and stacked die architectures. As a result, new thermal management solutions are needed to effectively dissipate heat and deliver greater device reliability.

Power supplies and controls for industries like computer servers and alternative energy are all managing higher electrical loads, which cause increased temperatures. The trend is creating a need for improved thermal management to dissipate heat in these devices, as this translates into improved performance, reliability, and lifetime. Improved thermal management also offers needed design flexibility.

Heat is the enemy of the devices and systems we use in our everyday lives. Improved thermal management is increasingly critical to maintaining the long-term performance and reliability of PCB system assemblies in virtually every industry.

Our ongoing joint research and development between Dow Silicones and Carbice Lab supports the continuous delivery of cutting-edge, next-generation thermal management solutions to meet market demands for innovation—now and into the future.

This case study was developed by a cross-discipline team representing materials and market expertise across Dow, Inc. in collaboration with our partner, Carbice. Founded in 2011, Carbice is an Atlanta, Georgia-based company that develops scalable interface solutions to protect the performance of semiconductors and electrical components from heat and stress in any physical environment. Dow and Carbice entered a partnership to produce multi-generational TIM product offerings in October 2024.