As part of its commitment to the health and safety of people and the environment, Dow continues to reduce its emissions of dioxins and furans. This involves a sampling and analytical program and technology development at sites around the world for the remaining emission points.

Dow's efforts to reduce dioxin emissions date back to the early 1980s, and the company has been publicly reporting emissions of dioxins since 1998. To date, we have spent more than $400 million on improvements to our processes and treatment technologies to reduce both the generation and emission of dioxins. Since 1995, our emissions to air and water have been reduced 80 percent.

Dow has reported total dioxin air and water emissions of less than eight grams globally for the last eight years. Reduction efforts continue, and progress continues to be made.

And in 2000, dioxins were added to both the U.S. Environmental Protection Agency's (EPA) Toxic Release Inventory (TRI), and Environment Canada's National Pollutant Release Inventory (NPRI) emission reporting requirements.

As a result, Dow submits emissions data for its sites in the U.S. that meet the reporting threshold, namely Freeport, Texas; Midland, Michigan; and Plaquemine, Louisiana. These data are included on the EPA web site.

Due to the shutdown of certain operations the Fort Saskatchewan site no longer meets threshold levels and has discontinued the reporting of dioxins and dioxin-like components.

The Toxics Release Inventory (TRI)

Each year the U.S. Environmental Protection Agency (EPA) requires manufacturing facilities in the chemical industry and many others to report emissions to air, water and land for more than 600 chemical substances if the releases exceed the threshold set by the EPA. The data are compiled by the EPA in its annual Toxics Release Inventory (TRI). The TRI was created in 1986 as part of the Emergency Planning and Community Right-To-Know Act.

All TRI data are posted on the EPA's Web site.

Dioxin and the TRI

Dioxin and dioxin-like compounds were included in the TRI for the first time in 2000. As a result, companies such as Dow must report their releases or emissions of dioxin to the EPA by July 1, each year. Under the TRI rules, manufacturing facilities must report annual releases of dioxins and dioxin-like compounds to the environment if they are created, processed or otherwise used in amounts of 0.1 grams (0.0035 ounces) per year or more. Dow has three U.S. sites that meet the reporting threshold of the U.S. EPA under TRI for dioxins. These sites are Plaquemine, Louisiana; Freeport, Texas; and Midland, Michigan.

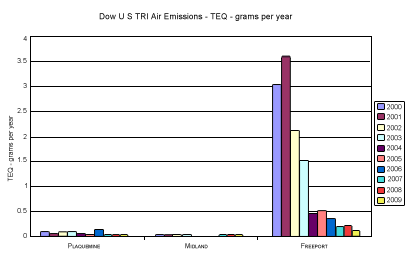

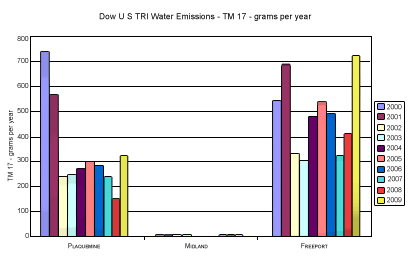

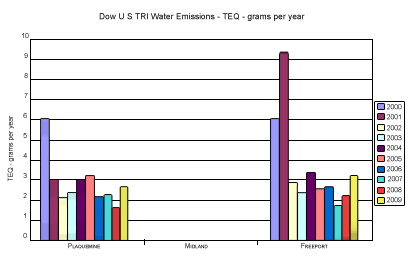

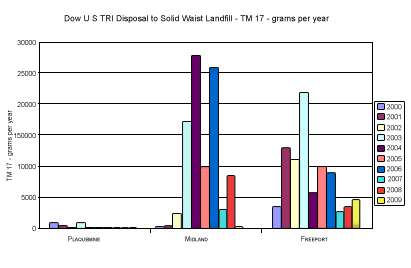

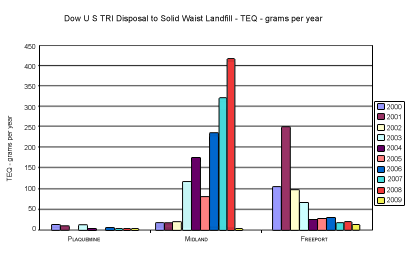

Dow’s TRI data reported since the year 2000 are shown on this web site with some notes of explanation. These data are expressed for TRI on a total mass basis and will numerically appear much higher than the same data shown in toxicity equivalents. For reference the data are also shown in terms of international toxic equivalents, or I-TEQ.

Since the conversion from mass to TEQ is dependent on the relative concentration of the different dioxin-like compounds, the changes from year to year may vary according to the reporting method. For example, the Freeport water emissions for the year 2005 are higher than the year 2004 on a TM17 basis but lower on a TEQ basis.

Dow Emissions of Dioxin to Air

Dow Emissions of Dioxin to Water

TRI Landfill Disposal

Dow disposes of solid waste in on-site regulated landfills. Any leachate is collected, treated and combined with other waste water on-site. (Thus, any contribution to emissions from this source would be included in the site water emissions.) All sites have test wells that monitor groundwater near the landfill and the landfills are distanced as much as possible from nearby communities.

The chart below shows the dioxins and furans disposed of in secure landfills at each site. The increases in disposal in 2003 and 2004 at Michigan Operations were due to remediation of historical contamination, and not current production.

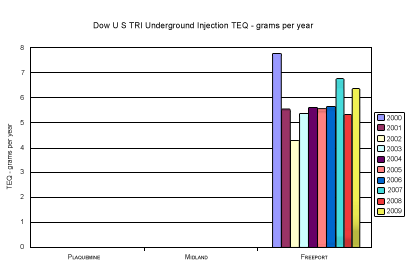

TRI Underground Injection

The EPA classify injection wells into Classes I to V depending on their use. Class I wells are used to inject hazardous or industrial and municipal wastes into deep underground geological formations. Class II wells are associated with oil and gas recovery, while Class III wells are used for extraction of minerals from deep underground caverns. Dow makes use of Class III wells for the mining of salt brines for the manufacture of chlorine and caustic — two of the major raw materials in the chemical industry. In order to recover salt and reduce water discharges, at some sites, spent brines are recycled back to the brine caverns. These recycled brines contain low levels of dioxins and furans attached to very small solid particles which tend to drop out to the bottom as they pass through the caverns. These wells are located in deep geological formations and the residual dioxins and furans have no possibility of migrating into the environment. Salt caverns have been used for storage of oil and gas and other hydrocarbons for many years and are considered very safe. For additional information, download the Underground Injection Control Program (450KB PDF) poster from the EPA Web site. These formations are very stable and studies have shown that small quantities of dioxins that may end up in these depleted wells present no risk to people or the environment.

Dow reports this deposition of dioxins and furans in the TRI category of underground injection. Currently, Freeport is the only Dow U.S. site that recycles its brine back to the brine wells.

TRI Treated Quantities

The TRI report is made up of two sections; the first is governed by the Emergency Planning and Community Right-to-Know legislation and covers the reporting of emissions and disposal of listed toxic chemicals. The second part is governed by the Pollution Prevention Act which covers pollution prevention and recycling data. For dioxins and furans, information related to recycling or energy recovery is not applicable because the quantities are so small. However, the total amount of dioxins and furans that are treated in incinerators, for example, is reported is this section. In the case of incineration, most of the dioxins are destroyed with state-of-the-art technology. Any dioxins and furans that are not destroyed or that are generated in the incineration process and leave in the flue gas stack are already included and reported with the air emissions data. For water streams, filtration and clarification are often used to remove dioxins and furans before the water is discharged. Dioxins and furans recovered in this way are either further treated in incinerators or may go to secure landfills. In either case, the emissions from these treatment processes are already included in the emissions reporting section of the report.

In the chart below, the estimated amount of dioxins and furans treated at each site is shown.