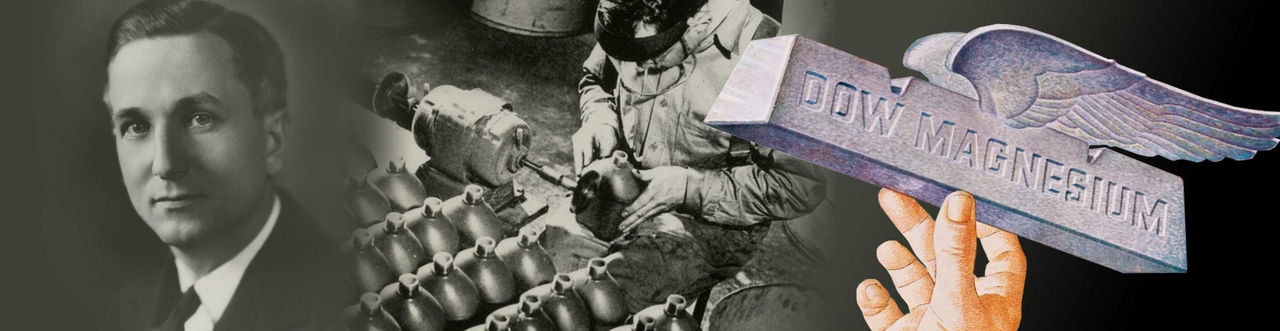

Willard Dow Grows Dow and Invests in Innovations to Support the Allies

Willard H. Dow was born in 1897, the same year his father began The Dow Chemical Company. After graduating from the University of Michigan, Willard entered the family business and took over as president of Dow at the age of 33, after his father’s death. He led the Company through the Great Depression and World War II, investing in new research, new products and new chemical production sites that helped the Allies win the war and helped position the U.S. for post-war growth.

Help on the Homefront

From magnesium for lightweight aircraft to STYROFOAM™ brand extruded polystyrene for lifeboats, Dow supplied dozens of products to the war effort. The research investments that Willard made in plastics and magnesium production during the Depression years were being rewarded.

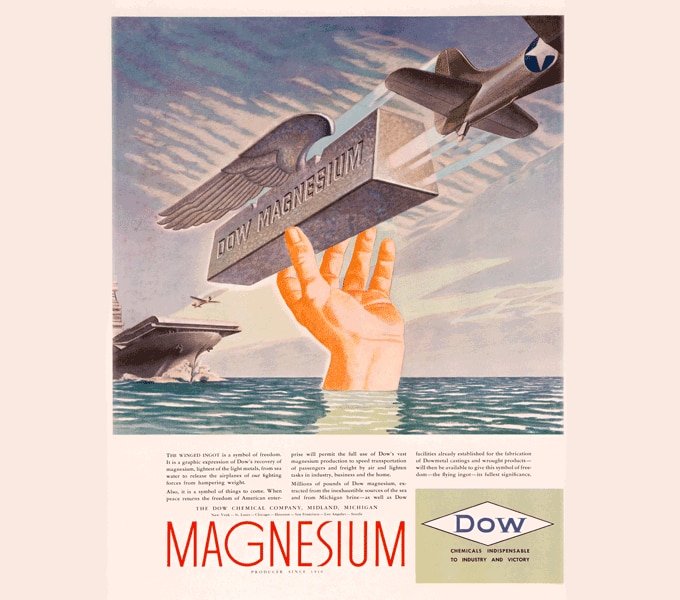

Magnificent Magnesium

It took only eight months to build The Dow Chemical Company’s Freeport magnesium plant. On January 21, 1941, under Willard’s leadership, the plant produced its first ingot of magnesium, mined from seawater. By the time the Japanese attacked Pearl Harbor, 11 months later, America’s prime source of magnesium was in full production.

After the attack, the U.S. government asked Dow to step up its magnesium production. Dow doubled its capacity in Freeport, built a second plant in Velasco, Texas, and added two new plants on the shores of Lake Michigan and Lake Huron in Michigan. In 1942, a critical year in gaining air supremacy over Europe, Dow-operated plants produced 84 percent of the nation’s magnesium output.

For Willard, the startup of the magnesium plant was the culmination of years of investment and research, and it completed a task his father had envisioned 16 years earlier. For the first time, man was mining the ocean, and Dow quickly became the main supplier of magnesium for U.S. and British war aircraft.

Rubber Tires, “Jungle Boots” and More

Dow also was a major contributor in supplying the United States with synthetic rubber. The onset of the war cut off U.S. access to 90 percent of the natural rubber supply. Buna-S rubber, the technology chosen by the government for synthetic rubber production, was made of styrene and butadiene. At the time, Dow was the only U.S. producer of styrene.

After Pearl Harbor, Dow agreed to provide its know-how to the government, which enabled the United States to meet its need for synthetic rubber during the war. Dow also operated several plants for the federal government to supply the armed forces with synthetic rubber.

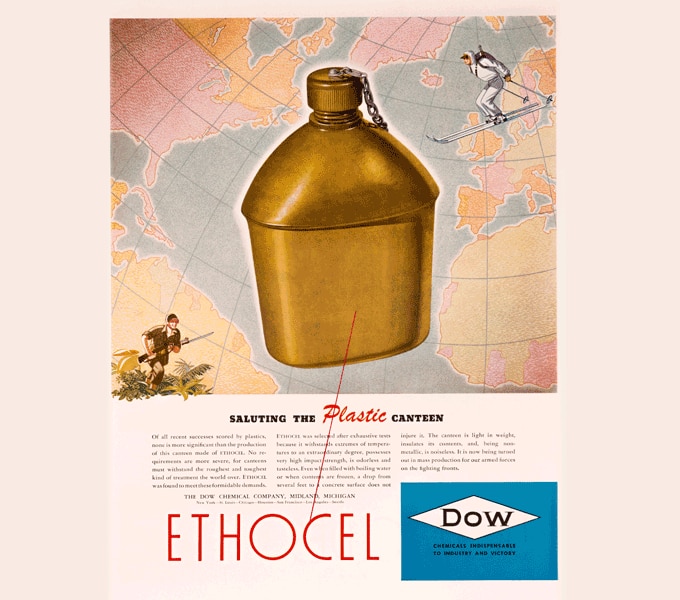

The U.S. government also needed an abundance of other materials that Dow could supply. ETHOCEL™, Dow’s first plastic, made significant contributions to the war. It was used for telephone headsets and mouthpieces, control knobs, dust goggles, airplane parts, explosive devices and canteens.

Dow’s solutions helped military troops on both the water and the ground. Another type of plastic, foamed polystyrene, which Dow later marketed as STYROFOAM™ with huge success, was used in rafts and lifeboats because of its buoyancy.

Brand-new from the research laboratory, SARAN™ resins were used for insect screens in tropical jungles. These insect screens proved to be less expensive and defied rot and rust. SARAN resins were also used to make shoe insoles, called “jungle boots,” that would prevent fungal foot infections. After the war, the plastic film would be developed for everyday use, including the well-known Saran Wrap™ plastic wrap.

Dow Corning: A War Baby

In 1943, Corning Glass and Dow formed Dow Corning, a joint venture that was established to explore the potential of silicone products for use by the military. The first product sold was Dow Corning® 4 Compound, an ignition-sealing compound that made high-altitude flight possible. After the war, Dow Corning grew to become the largest silicone product producer in the world.

In the fall of 1943, Dow distributed a booklet to employees, titled “Your Job and Victory,” detailing Dow’s role in the war effort. The booklet carried a message from Maj. Gen. Lucius D. Clay, then director of material for the army, who wrote: “The final decision of this war will come, as always on the battlefield itself, but behind the final patch of land, on which the last Axis soldier will be beaten into unconditional surrender, will lie the chemical laboratory which prepared the way for his defeat.” For Dow employees, the message was clear: Their work was a powerful force behind the Allies.

Responding to the Challenges of an Era

To survive over time, companies must respond to the challenges of their era. Willard’s investment in research into petrochemicals, plastics and magnesium not only helped Dow respond to the war effort, but also positioned Dow for success after the war – when there was spectacular growth in demand for chemical products. By the time he was killed in an airplane crash in 1949, Willard had grown the Company by seven-fold and established a product base for greater growth to come.

It was his conviction that the opportunities in chemistry were boundless. “There is always room out in front – room for all without crowding and work for generations to come,” Willard said.

At nearly 125 years, Dow continues to use its science and innovation to respond to the challenges of the era and to produce products that solve today’s challenges.

® ™ Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow. The Corning portion of the Dow Corning trademark is a trademark of Corning Incorporated, used under license.

™ Saran Wrap is a trademark of S.C. Johnson & Son, Inc.